- Home

- Blog

- Material & Life

- Let our Static Dissipative TPE & Conductive TPE enrich your product design

Let our Static Dissipative TPE & Conductive TPE enrich your product design

2024-10-24

Image by Wellplast, https://www.wellplast.com/esd-materials/

· Static Dissipative TPE

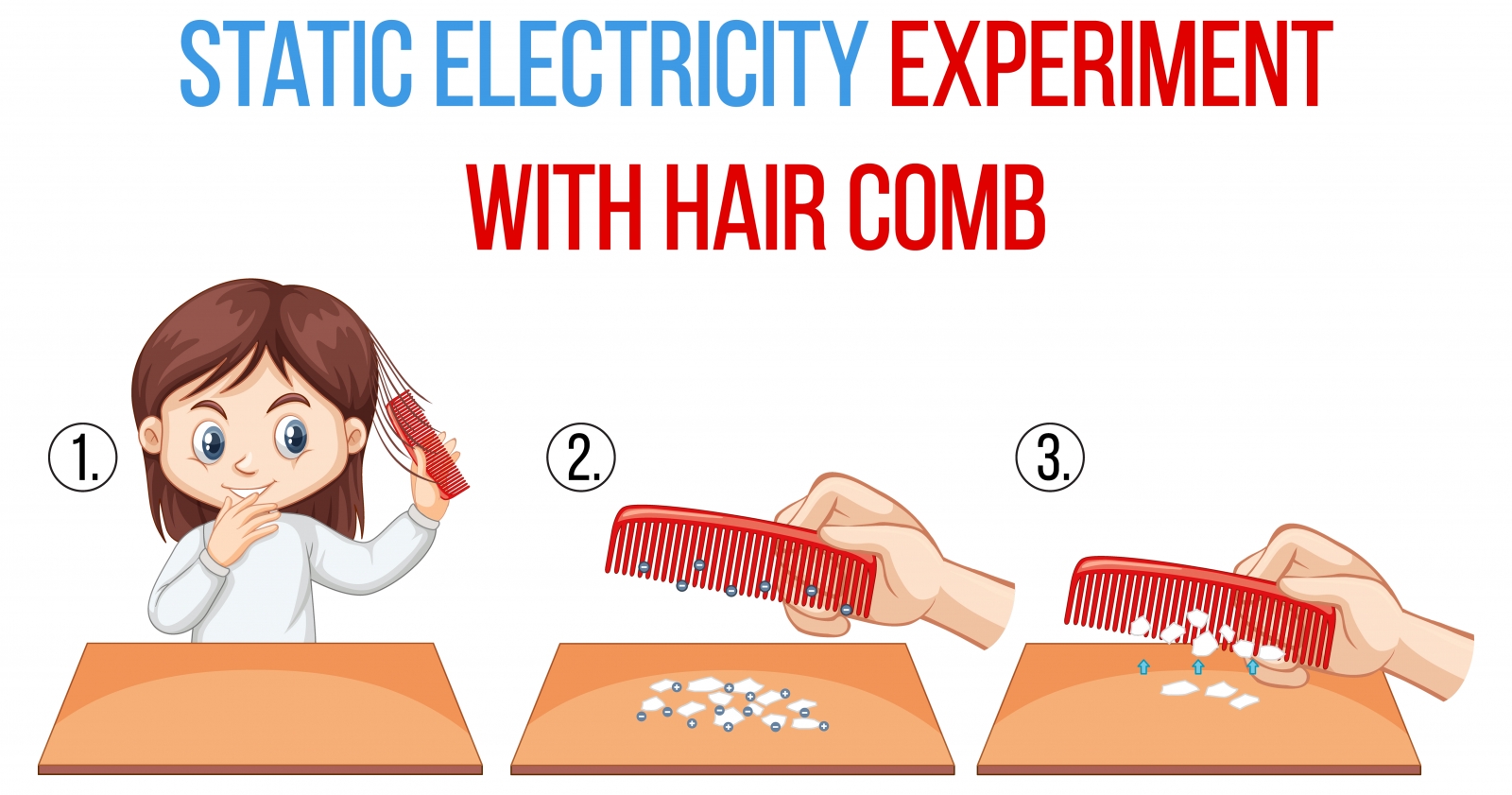

Have you ever had a static shock in your life? For example, when you get your sweater or pullover out of your clothes dryer, you will get the static shock at the same time, or you run the plastic comb through your hair to untangle the knots in a relatively drying season, and you will get the static shock.

The static electricity is like a naughty child does not always appear in our lives, it only occurs in certain situations. It is sometimes caused by human factors, such as the case of running hair through the plastic comb in drying season as the previous paragraph mentioned. This phenomenon usually needs to allow two items to rub against each other, and these two things will transfer the electrons from one side to another side, then leading to the happen of static. Therefore, you can understand that it is a process of exchanging positive and negative charges.

Image by Freepik

Moreover, static electricity can be affected by natural factors, the wintertime can appear the more static electricity than the summertime, due to the wintertime usually being drier than summertime, and the humid air easily conducts electricity. Therefore, compared with the summertime, static electricity more easily happens in the wintertime.

Phon Tech knew the issues you faced, all of us have been bothered by this issue since we were children. Therefore, we recently developed a new functional TPE series for the static dissipative, we expect that our material can allow each industry to solve or reduce these issues, and increase their customer satisfaction or their field of product application.

Phon Tech knew the issues you faced, all of us have been bothered by this issue since we were children. Therefore, we recently developed a new functional TPE series for the static dissipative, we expect that our material can allow each industry to solve or reduce these issues, and increase their customer satisfaction or their field of product application.

- The traits of our static dissipative TPE

- The usual surface electric resistance of static dissipative is between 106 and 1010 ohms per square, and we currently have matched this range with our material, and other electrical resistivity ranges can be customized.

- Adhesion to polyolefins (PP, PE) in multi-component injection moulding.

- Reduces static build-up.

- Meets regulatory compliance requirements of ESD.

- The hardness range can be customized.

· Conductive TPE

“What kinds of material do you think is the conductive material, metal material or plastic & rubber material”, this is a simple and easy question for all of us, which also be asked by each chemical tutor in our school life. Moreover, most people usually choose the metal material for this question, and It is truly correct under this question, no doubt. Therefore, most conductive elements of current electronic products are made of metal materials.

However, because the price of each metal will increase after its natural reserves steadily decrease in the future, it will directly affect the price of general electronic products. Therefore, these elements need to be produced through other possible conductive materials to solve this issue.

Moreover, most electronic products have pursued the trait of being lightweight in recent years. Therefore, part of product development started to decline the metal parts used, and inclined to use more plastic parts in the whole design.

Phon Tech also understands this trend through our market research. Hence, we spend period of time developing this reliable conductive TPE material for our current customers and different fields of potential customers.

- The traits of our static conductive TPE

- The usual surface electric resistance of static dissipative is between 103 and 105 ohms per square, and we currently match this range with our material, and other electrical resistivity ranges can be customized.

- Adhesion to polyolefins (PP, PE) and in multi-component injection moulding.

- Meets regulatory compliance requirements of ESD.

- The hardness range can be customized.

Article Classification

Recent Articles

- Luggage wheels with PHOENIX™ TPE can take you further

- Let our Static Dissipative TPE & Conductive TPE enrich your product design

- Why TPE is the perfect material for your Fish Bait

- TPEs: Ideal Materials for Syringe Gasket Applications

- How does TPEs help you relax from the daily

- Understanding GHG Emission Quantification and Verification

- PHOENIX™ TPEs care about you, because you are our baby.

- GRS & RCS: Certification For Recycled Materials

- PHOENIX Materialize Your Vision for Sustainable Future

- PHOENIX™ Antimicrobial TPEs help you combat bacteria

- To fast display yourself on the PHOENIX™ TPEs material-made product.

- Learn TPE from daily dental care

- TPE - The Small but Important Piece in Bottle Caps

- Life Matters: High-quality PHOENIX™ TPEs for Medical Applications

- The crucial elements in human life

- The indispensable utensils in the KITCHEN

- The recyclability of PHOENIX™ TPEs

- A Peek Into A Ballerina's Dance Bag

- How to discover the Phoenix™ at 2021 Tour De France!?

- TPE: Enjoy cycling with comfort grips

- Your great company during Covid-19 pandemic!!

- TPE: Why Does It Matter To The Hospital Bed Caster

- Compression Set of Thermoplastic Elastomers