- Home

- Blog

- Material & Life

- To fast display yourself on the PHOENIX™ TPEs material-made product.

To fast display yourself on the PHOENIX™ TPEs material-made product.

2022-09-14

Image by Scott Nodine/iStock/Thinkstock

Have you ever noticed any marks on the food package?

Have you ever noticed any marks on the food package?

Food packaging has already been used by the public for a long time, and the early packaging can be made with a glass bottle and metal can, those ways of food packaging allow the majority to get the great flavour of food, which the producers expect to present to the customers. Due to the people, lifestyles and consumer methods have changed, the method of food-package has already separated into different forms, and most command ways of food packaging steadily change to plastic and paper packaging from glass and metal one.

However, whether you got your stuff or food from a glass bottle, metal can, paper packaging or plastic packaging, most of us generally prefer to observe the out pack of product, and the thing we usually notice is what kinds of ingredients or elements included in this product, where does this product made from, when is it last enjoys date or how much should I cost, and something else, those things usually allow us to know more detail on the product.

How do producers display this kind of information to the public?

According to the former paragraphs, we have known that customers can get various information on each food package. That information generally can be displayed in distinct ways, which included the way of digital printing or laser printing and laser marking.

Basic things you need to know with Digital & Laser printing.

The method of digital printing and laser printing is usually used on the plastic package and paper packages, such as the package of cookies, biscuits and other snacks, or the shopping bag in which you buy your clothes from famous clothes shops, for example, ZARA, H&M, GAP, etc. There is a tendency that this kind of method to be easy for each producer to display each piece of information and figure on the package with ink, it also does not need to spend huge costs on the printing machine.

Image by REUTERS/Charles Platiau

However, there is a point that needs to be concern by users, who use digital printing machines and laser printing ones, and this point is about the issue of ink, if we print any mark on the paper package, it usually can be successfully marked, but we need to concern the ingredient or types with ink when we print marks on the plastic package.

As far as we knew that plastic material sometimes can be separated into polar plastics and non-polar ones, so when you want to display any information on your plastic product through digital & laser printing equipment, you need to notice that is your ink suitable for your product, for example, is this ink can successfully marl on your product, or if this ink mark on your product, and is it can colour on it for a long time? If those kinds of points do not consider by you before you start printing information, it could affect your clients and users of the end product.

Another way to show your information on your product.

According to the second paragraph we have mentioned totally two types of methods which can help us to print or mark any information on the product, and we have already known digital or laser printing and its basic information. Moreover, another way of printing information on your product which can use laser marking.

The method of laser marking or engraving usually can be used on variant materials, which included glass, metal, paper, plastic and others, which you can find in the below video.

Video made by Triumphlaser, all credits go to Triumphlaser.

Moreover, the laser marking machine can allow users to print and mark every piece of information on each stuff, and you do not need to spend lots of time on the issues of can this information is successfully shown out, or can they be permanently exhibited on your stuff.

The elemental things need to be concerned by users

There is an elemental point that needs to be considered by the users of laser marking when they try to use this printing method and start getting this kind of equipment. These kinds of laser marking equipment usually separate various types of them, and you can generally know three of them in each industrial, first one is a fibre laser machine, another is a CO2 laser machine, and the other is a UV laser machine.

Therefore, the way of separating those three types of machines through which kind of material of the product you require to marking result, which as we said at former paragraphs, laser marking can easily show information on various material, such as metal, plastic, paper, glass, wood and even stones. However, their way to create any mark is often the same, which is focused beams of light that contain high levels of energy. Its energy is transferred in the form of heat when a laser beam hits a range of surfaces, which will create black and white words or figures, and sometimes shown through engraving way.

Different points of each laser equipment

3. UV Laser Marker

However, whether you got your stuff or food from a glass bottle, metal can, paper packaging or plastic packaging, most of us generally prefer to observe the out pack of product, and the thing we usually notice is what kinds of ingredients or elements included in this product, where does this product made from, when is it last enjoys date or how much should I cost, and something else, those things usually allow us to know more detail on the product.

Image by Anastasia Igolnikova, https://www.behance.net/gallery/42243057/Kelloggs-Fruit-chips

How do producers display this kind of information to the public?

According to the former paragraphs, we have known that customers can get various information on each food package. That information generally can be displayed in distinct ways, which included the way of digital printing or laser printing and laser marking.

Basic things you need to know with Digital & Laser printing.

The method of digital printing and laser printing is usually used on the plastic package and paper packages, such as the package of cookies, biscuits and other snacks, or the shopping bag in which you buy your clothes from famous clothes shops, for example, ZARA, H&M, GAP, etc. There is a tendency that this kind of method to be easy for each producer to display each piece of information and figure on the package with ink, it also does not need to spend huge costs on the printing machine.

Image by REUTERS/Charles Platiau

However, there is a point that needs to be concern by users, who use digital printing machines and laser printing ones, and this point is about the issue of ink, if we print any mark on the paper package, it usually can be successfully marked, but we need to concern the ingredient or types with ink when we print marks on the plastic package.

As far as we knew that plastic material sometimes can be separated into polar plastics and non-polar ones, so when you want to display any information on your plastic product through digital & laser printing equipment, you need to notice that is your ink suitable for your product, for example, is this ink can successfully marl on your product, or if this ink mark on your product, and is it can colour on it for a long time? If those kinds of points do not consider by you before you start printing information, it could affect your clients and users of the end product.

Another way to show your information on your product.

According to the second paragraph we have mentioned totally two types of methods which can help us to print or mark any information on the product, and we have already known digital or laser printing and its basic information. Moreover, another way of printing information on your product which can use laser marking.

The method of laser marking or engraving usually can be used on variant materials, which included glass, metal, paper, plastic and others, which you can find in the below video.

Video made by Triumphlaser, all credits go to Triumphlaser.

Moreover, the laser marking machine can allow users to print and mark every piece of information on each stuff, and you do not need to spend lots of time on the issues of can this information is successfully shown out, or can they be permanently exhibited on your stuff.

The elemental things need to be concerned by users

There is an elemental point that needs to be considered by the users of laser marking when they try to use this printing method and start getting this kind of equipment. These kinds of laser marking equipment usually separate various types of them, and you can generally know three of them in each industrial, first one is a fibre laser machine, another is a CO2 laser machine, and the other is a UV laser machine.

Therefore, the way of separating those three types of machines through which kind of material of the product you require to marking result, which as we said at former paragraphs, laser marking can easily show information on various material, such as metal, plastic, paper, glass, wood and even stones. However, their way to create any mark is often the same, which is focused beams of light that contain high levels of energy. Its energy is transferred in the form of heat when a laser beam hits a range of surfaces, which will create black and white words or figures, and sometimes shown through engraving way.

Different points of each laser equipment

1. Fibre Laser Marker

Fibre lasers belong to high-output lasers, which usually could print with the traits of high power, fast scan speeds, and the smallest marking unit size.

Moreover, its wavelength usually locates around 1064 nm, which is within the standard wavelength range, and its capable of marking a wide range of materials, including metals and resins. Furthermore, high power is particularly suited for marking and deep engraving on metal. However, fibre laser markers cannot be used to mark transparent objects like glass and other transparent plastic as the light easily passes through them.

2. CO2 Laser Marker

This kind of laser stimulates CO2 gas to bring about the laser light, so it belongs to the gas laser group, and its laser emits in the mid-infrared areas between 9,000 nm to 11,000 nm. Moreover, people commonly use wavelengths around 10600 nm, which cover various organic materials that require distinct wavelengths which could be plastic and wood. Furthermore, it can easily be absorbed by transparent materials and glass, so you also can get great marking results on those materials. However, it is hard to mark metal due to the laser light has almost not been absorbed by them.

3. UV Laser Marker

This laser maker has a wavelength of around 355 nm. It is in the "cold laser" category which emits less energy, small heat-affected areas, fine marking spots, and has high efficiency. It provides great solutions for offering lower power for marking heat-sensitive materials such as plastic, glass and many organic or soft products. It is less likely than other laser marker equipment to burn the material, and it can efficacity prevent materials from deformation and damage after finishing the laser marking. Moreover, you can discover that its word or picture result looks like the printing, which is only displayed on the surface, and it does not like other laser marking machines, which show their result through engraving way.

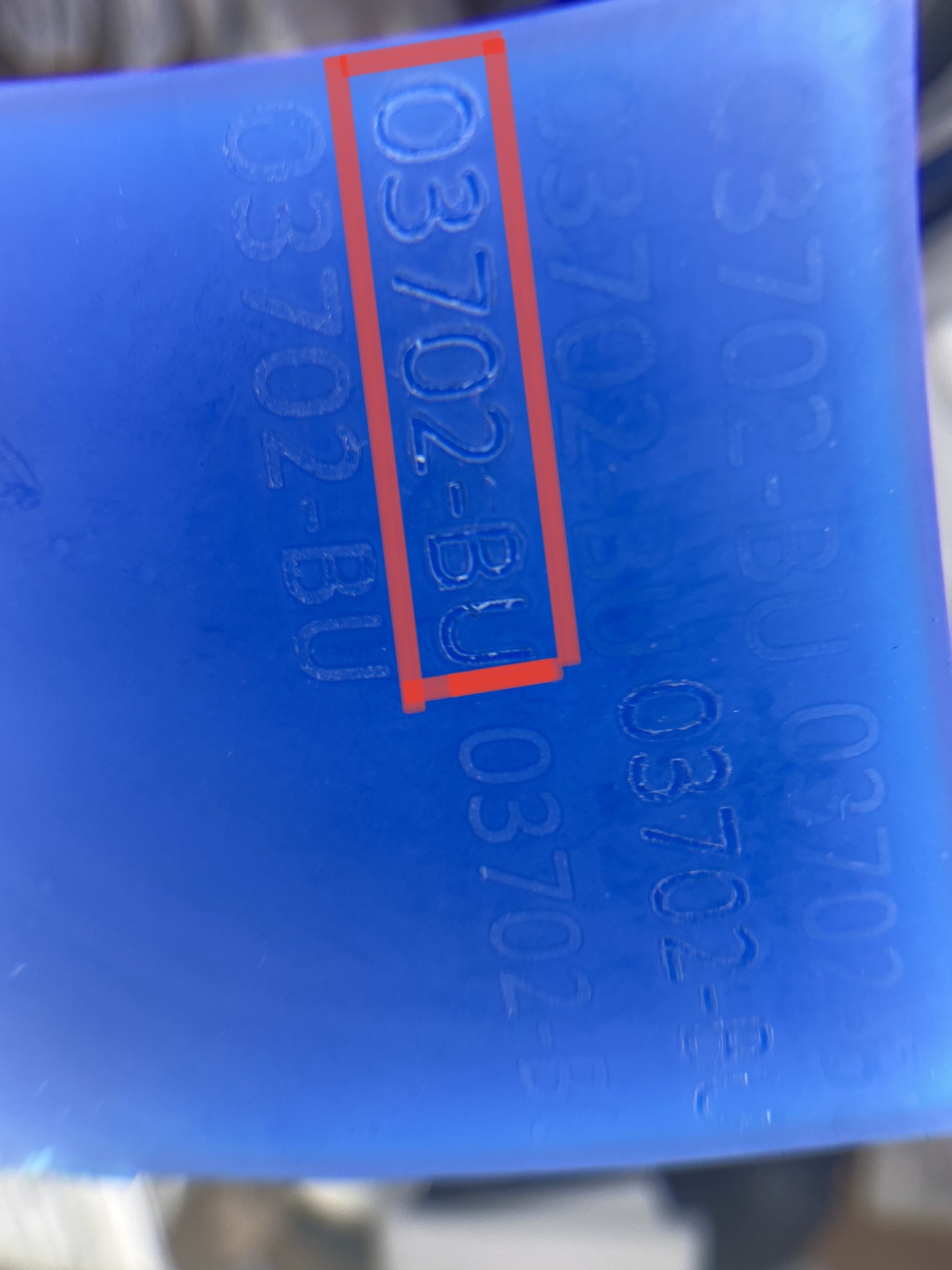

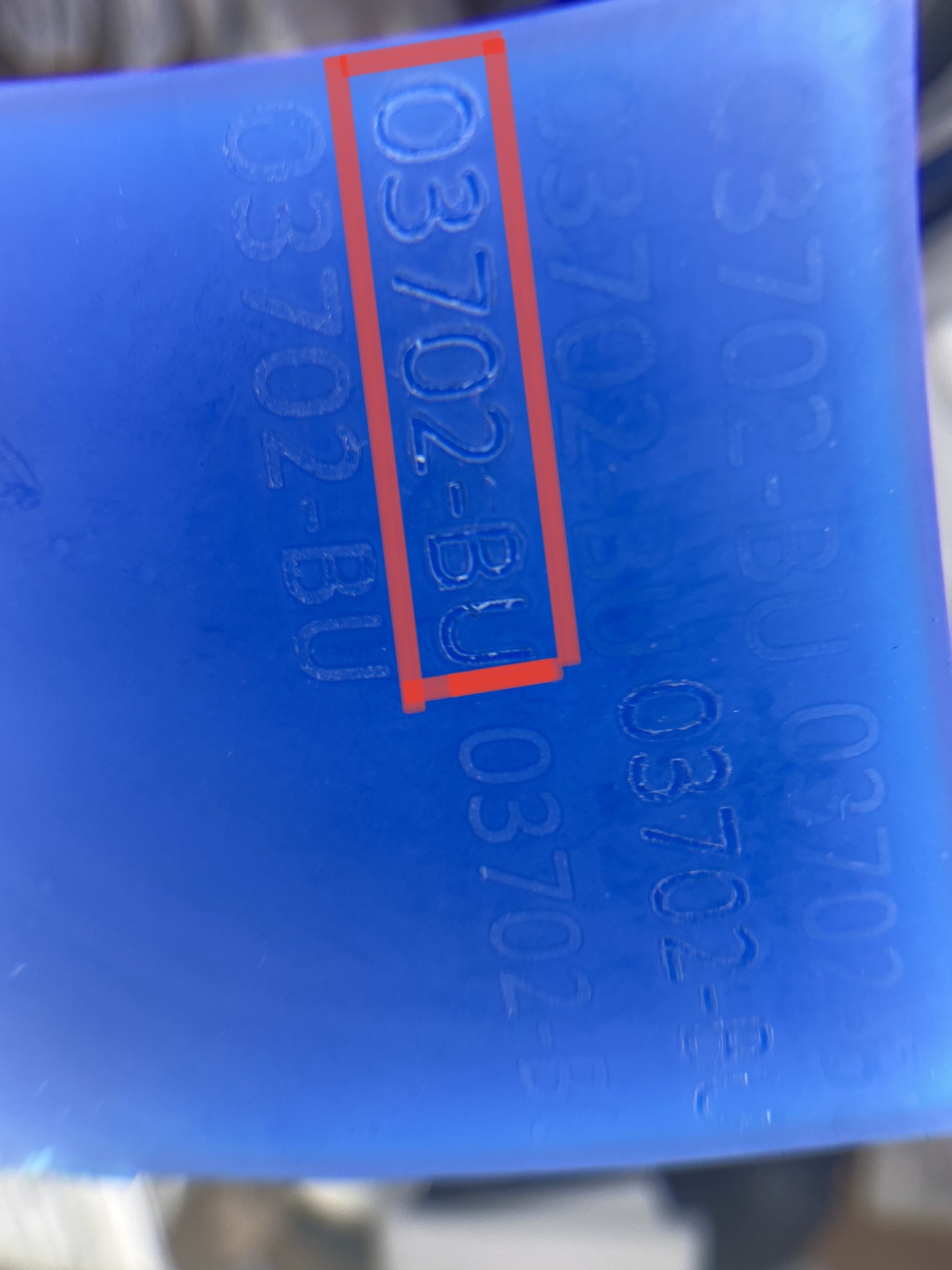

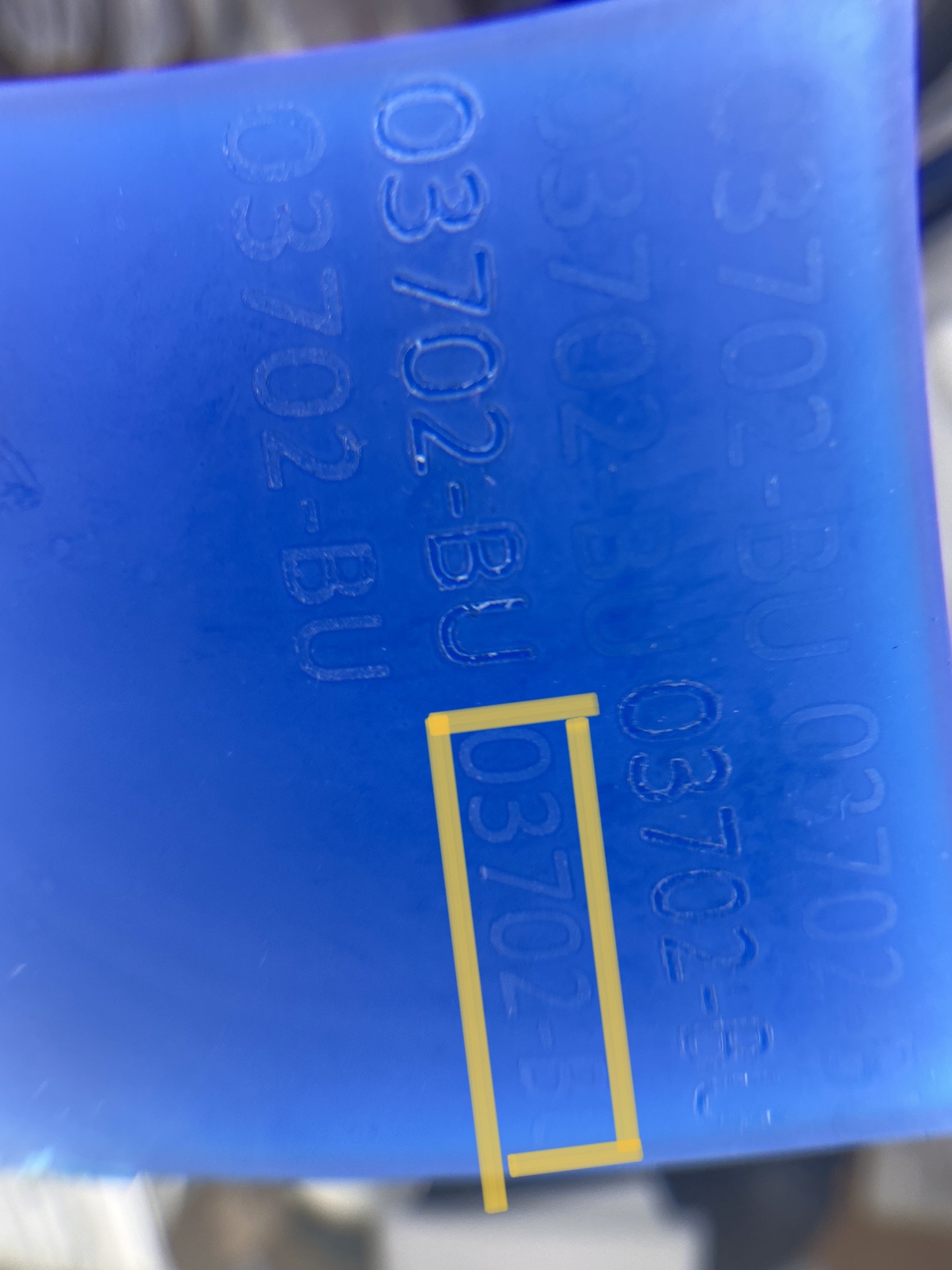

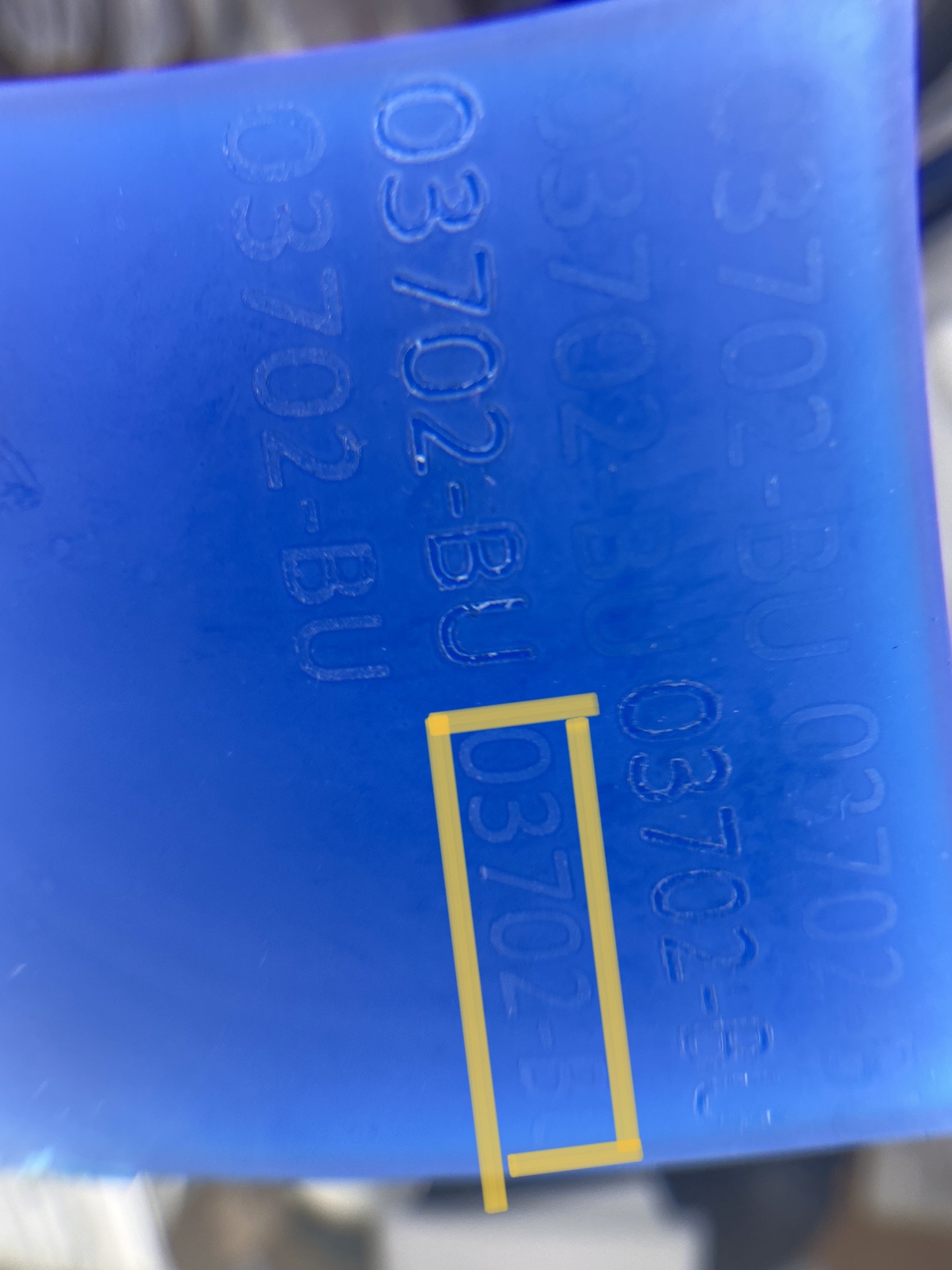

Moreover, as you can see in the former two figures, both of them are specimens of the Phoenix 03 series, those two pictures display that our material can successfully be marked through the laser marking equipment of CO2 and UV.

Currently, we have tested our material of cap liner with our customer, and we discover that our material can mark any word and QR code with a specific condition, so, it might help some demanders to mark anything on the product using our TPE material without any laser or colour additive.

To sum up, each laser marking equipment can successfully mark on distinct forms of stuff and materials, which means that although they can mark with a wide range of products series, you cannot expect that you can laser any material or stuffs through only one type of laser equipment, due to that there are lots of traits need to concern, which included the laser power, speed, material, size of target and others.

Moreover, all of this information we writing through our experience and formal source on the internet, so it doesn't mean that our article can correctly solve your problem when you face any issue, but we are great to discuss any laser issue of TPE material with you if you are willing to sharing them with us.

Reference list

Moreover, as you can see in the former two figures, both of them are specimens of the Phoenix 03 series, those two pictures display that our material can successfully be marked through the laser marking equipment of CO2 and UV.

Currently, we have tested our material of cap liner with our customer, and we discover that our material can mark any word and QR code with a specific condition, so, it might help some demanders to mark anything on the product using our TPE material without any laser or colour additive.

To sum up, each laser marking equipment can successfully mark on distinct forms of stuff and materials, which means that although they can mark with a wide range of products series, you cannot expect that you can laser any material or stuffs through only one type of laser equipment, due to that there are lots of traits need to concern, which included the laser power, speed, material, size of target and others.

Moreover, all of this information we writing through our experience and formal source on the internet, so it doesn't mean that our article can correctly solve your problem when you face any issue, but we are great to discuss any laser issue of TPE material with you if you are willing to sharing them with us.

Reference list

- CO2 laser - functionality and areas of application, https:/www.troteclaser.com/en/learn-support/helpcenter/co2-laser

- CO2 Laser Marking | Knowledge | Laser Marking Basics | KEYENCE International Belgium, https://www.keyence.eu/ss/products/marking/lasermarker/knowledge/co2-laser.jsp

- Laser Marking Types | Basic Knowledge | Laser Marking Central | KEYENCE Americ, https://www.keyence.com/ss/products/marking/laser-marking-central/basics/wavelength.jsp

- Introduction To Fiber Laser Marking, https://www.photonicsonline.com/doc/introduction-to-fiber-laser-marking-0001

- Fabrication and characterization of a fused silica-based optical waveguide with femtosecond fibre laser pulses. J Tang, C Chen, T Chang, S Wang, L Chau, W Wu, 2012

Article Classification

Recent Articles

- Luggage wheels with PHOENIX™ TPE can take you further

- Let our Static Dissipative TPE & Conductive TPE enrich your product design

- Why TPE is the perfect material for your Fish Bait

- TPEs: Ideal Materials for Syringe Gasket Applications

- How does TPEs help you relax from the daily

- Understanding GHG Emission Quantification and Verification

- PHOENIX™ TPEs care about you, because you are our baby.

- GRS & RCS: Certification For Recycled Materials

- PHOENIX Materialize Your Vision for Sustainable Future

- PHOENIX™ Antimicrobial TPEs help you combat bacteria

- To fast display yourself on the PHOENIX™ TPEs material-made product.

- Learn TPE from daily dental care

- TPE - The Small but Important Piece in Bottle Caps

- Life Matters: High-quality PHOENIX™ TPEs for Medical Applications

- The crucial elements in human life

- The indispensable utensils in the KITCHEN

- The recyclability of PHOENIX™ TPEs

- A Peek Into A Ballerina's Dance Bag

- How to discover the Phoenix™ at 2021 Tour De France!?

- TPE: Enjoy cycling with comfort grips

- Your great company during Covid-19 pandemic!!

- TPE: Why Does It Matter To The Hospital Bed Caster

- Compression Set of Thermoplastic Elastomers